Factory Plot

ch 1

work is usually hectic. seems like there are lots of things going. Alex wants to get work done “before the fires break out.”

A big order is so late (7 weeks) the people at the plant weren’t even aware of it. they have the parts ready but can’t assemble because subassembly is missing. the subassembly parts are there but are not being worked on, instead some other urgent parts that took an hour and a half to setup.

So the parts are all there but they’re not working on it and they’re about to wast an hour and a half of setup. Super uncoordinated! now they have to spend time deciding what to do as well when they’re already in a pinch.

the machines aren’t ready on demand. when they find out they need to do something urgently they don’t have excess capacity to work on this thing. it seems like they have spare parts but they can’t work on them because everything is occupied. if some bad luck and urgent orders come up they have to disrupt other production to a large degree.

that’s like not having open slots on your schedule when things come up or take longer than expected.

Peach tells Alex his plant is lots of losing money. Alex partly blames it on not having enough employees. Alex has three months to turn things around.

The machine they needed for the late order is now broken. It’s the only one they have of that type.

ch 2

the machine is working again and almost everybody is working on the late order. parts per worker is low but at least they’re getting the really important order shipped that day.

Alex says they can’t always do things like these because it’s really inefficient.

Goldratt says that there’s something good in what you did to solve an emergency. In this emergency they had to really focus on a really important order and give up general “efficiency”. You wouldn’t want almost the whole plant working on a single order, but the lesson is to focus on throughput of the important things rather than general efficiency.

I don’t think I noticed this on my first read. I think I wouldn’t have noticed this if I hadn’t read the emergencies section in Introduction to Theory of Constraints.

Alex tries to figure out why things aren’t working. They’ve got good people, machines and materials. He blames the competition from Japan whom I think did some of the things that Goldratt says are good, e.g. Toyota.

Alex has already costs a bunch and his plant is efficient. He contemplates making it even more efficient, but he figures it’s already so efficient there’s not much more to squeeze out.

They have lots of inventory, but the material does end up as finished products on time.

Late orders are late in America. Stuff has to be expedited to get done on time.

Alex says gremlins are causing trouble, jokingly. But actually they are. The gremlins represent variance and Alex’s balanced plant is not robust against variance so everything turns to chaos.

ch 3

Peach calls in leaders of the plants to tell them the whole division is in danger. Alex could be totally without a job in three months.

ch 4

Alex meets Jonah.

Alex is about to go give a talk about how robots will revolutionize productivity in American manufacturing. Jonah’s isn’t impressed.

Alex says the robots increased productivity but Jonah asked whether they increased profits, which they haven’t.

They didn’t lay people off, inventory has not gone down and sales hasn’t increased so Jonah concludes the robots can’t have increased productivity.

Alex argues his efficiencies are up and costs are down. Alex says this is important. The robots are running constantly. If they didn’t they would lose savings on cost per part.

Jonah already knows that their inventories have gone way up and that they’re late on everything.

If they’re running everything all the time at max capacity then some stations will produce more than the next station can handle. Therefore inventory piles up some places.

- why is everything late? figure it out yourself

Jonah says the plant is inefficient according to the right measurements. Alex is using wrong measurements because of poor thinking. He says the world hasn’t been critical of production/organization theory and are almost not thinking at all.

Jonah asks Alex “what is productivity?” he answers “value added per employee equals…”

Jonah manages to get Alex conclude that productivity is accomplishing something in terms of your goal. Alex says it’s obvious but then says that one goal of his company is to increase efficiencies. Jonah says every company has one goal. Alex suggests power and market share. Jonah leaves Alex to figure it out for himself.

The goal is to make money.

The meeting with Jonah was 2 weeks ago when Alex didn’t know the whole division was in danger of being shut down.

ch 5

Alex remembers the talk with Jonah and starts doubting that anyone at the division knows what they’re doing.

Alex leaves the meeting to ponder what the goal of every business is.

Alex figures out cost-effectiveness is not the goal. Because they have lots of inventory bought at great prices, but what for?

They’ve laid off people so it can’t be to supply jobs.

Alex sees no reason why it couldn’t be producing products but Jonah said it wasn’t that.

It couldn’t be quality since UniCo has improved its quality to great and are still losing money. He thinks quality is important but not enough. Alex thinks the problem is quality can be costly. He concludes quality and efficiency are the goals. But he’s not satisfied. He can think of efficiently produced quality products that went bust.

He thinks of technology, but he remembers R&D isn’t usually emphasized in organizations and also thinks the just having the newest best machines wouldn’t make his plan productive either.

Alex realizes the goal is not to fill warehouses with products. They want to sell the products. So the goal could be sales. But Jonah said it wasn’t market share and what’s the point of selling a lot if you can’t sell at a profit.

He realizes the big thing is money. So he has to stop the company from losing money otherwise it’ll have to shut down. Then he realizes there’s no point in running the company if it just breaks out even. The goal is to make money.

So being productive is making money. The other things he thought of are just means of achieving this goal.

I remember patio11 telling about programmers not being fully aware of this. He said they shouldn’t sell themself purely on technical explanations but telling their clients how they can make them money or solve a problem.

ch 6

Alex walks by three idle workers and gets upset at their supervisor. Their quotas were finished and now they’re just doing some busywork because Alex pushed the supervisor. Alex realizes what they’re doing might not be productive at all, it might not earn them any money.

Alex contemplates all the variables and complexity of the plant wonders how can he control it and make sure they’re making money. The measurements they make are supposed to help with that, but he’s not convinced.

Alex asks Lou the minimum necessary measurements in order to know whether they’re making money.

Absolute money made is a start but we have to consider it relative to how much was invested. ROI. But lots of profitable businesses with good ROI have gone bankrupt because they ran out of money. So cash flow is necessary too. Net profit, ROI and cash flow are what matters.

You need enough cash to survive, if you go below the required amount the company is finished. So nothing else matters when your cash flow is bad. They realize their cash is running out.

Lou blames the poor performance on lots of common things. The union, work ethic, low cost foreign labor, not caring about quality, etc.

Alex wonders whether he can prioritize one of the three measurements at the expense of the other two. He realizes you have to increase all three simultaneously. His goal is clear.

He has to figure out how to make what happens in the plant connect with increasing those three measurements. He’s stuck.

I think the goal in the plant is throughput. Finished products that they can sell.

Alex talks to a supervisor at the plant what impact they’ve had on the three measurements. The supervisor doesn’t think about those three, he has lots of other measurements he worries about.

I think Alex realizes that he has to think about something to connect the two. He can’t expect the plant workers to think about net profit, ROI and cash flow, those are for the HQ to think about. They need some measurements in the plant to be a proxy for making money.

ch 8

Alex is on a call with Jonah.

Jonah says the goal can be expressed in different ways. You need to express the goal which can guide daily operations at a plant which net profit, ROI and cash flow can’t. Jonah’s measurements are throughput, inventory and operational expenses.

I remembered throughput but that couldn’t be it alone because you at least need to spend less than you sell for. Inventory is less obvious and seems less direct, I do remember it was important though.

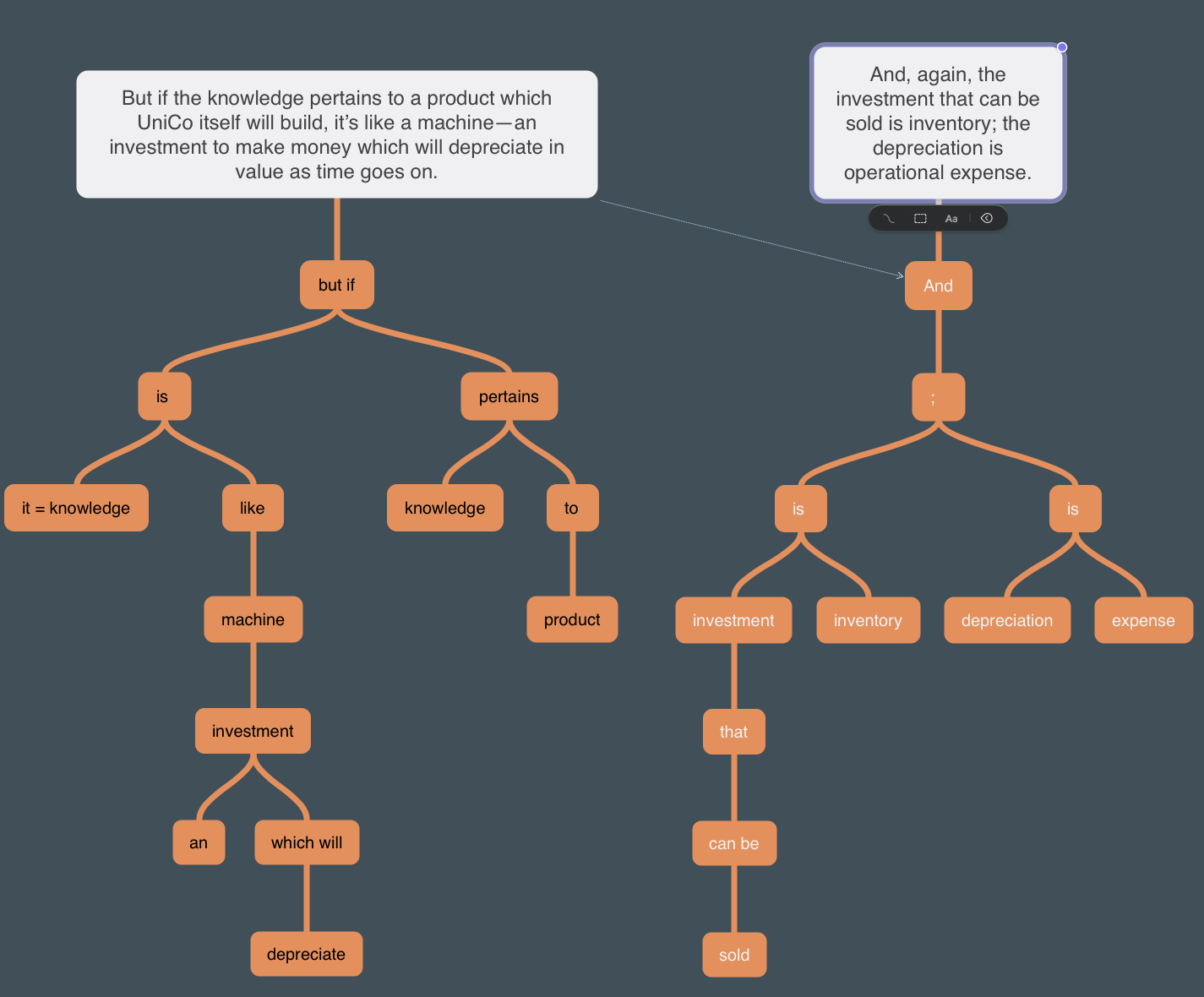

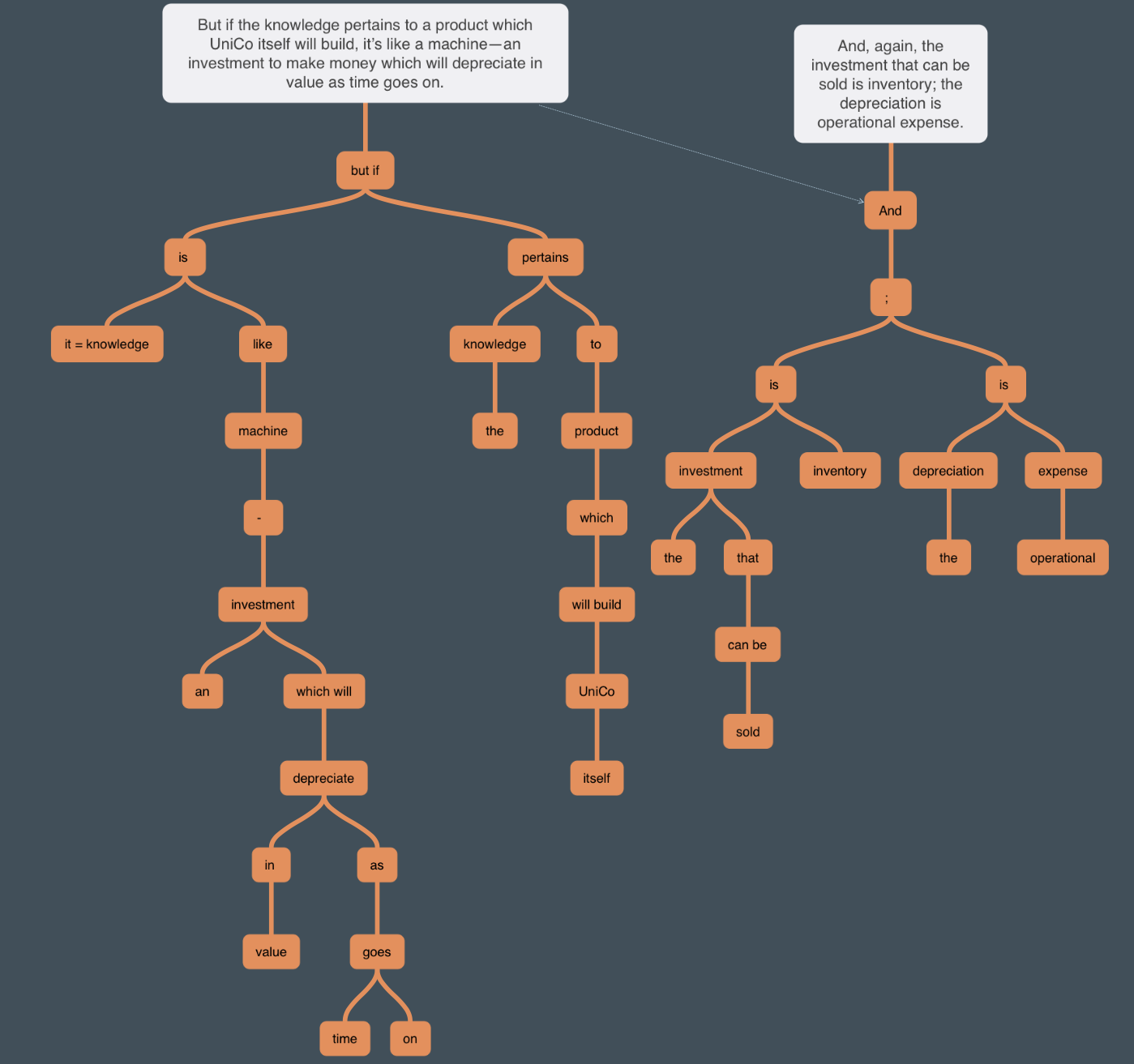

Jonah:

“Throughput,” he says, “is the rate at which the system generates money through sales.”

Alex asks if he can substitute sales with production. If you produce but don’t sell you’re producing something no one wants. You’re filling up warehouses, not making money.

Jonah:

“The next measurement is inventory,” he says. “Inventory is all the money that the system has invested in purchasing things which it intends to sell.”

“Operational expense,” he says. “Operational expense is all the money the system spends in order to turn inventory into throughput.”

These are carefully designed definitions. Changing one of them likely causes change in another.

“But what about the labor invested in inventory? You make it sound as though labor is operational expense?”

“Judge it according to the definitions,” he says.

“But the value added to the product by direct labor has to be a part of inventory, doesn’t it?”

“It might be, but it doesn’t have to be,” he says.

“Why do you say that?”

“Very simply, I decided to define it this way because I believe it’s better not to take the value added into account,” he says. “It eliminates the confusion over whether a dollar spent is an investment or an expense. That’s why I defined inventory and operational expense the way I just gave you.”

I’m confused here.

Labor would be operational expense since it is money spent turning inventory into a product which gets sold. But that inventory will have value added from the labor. So if inventory was the value of things that is intended to sell then then the labor would be counted as part of both inventory and operational expenses. But Jonah defined inventory as investments in things purchased which is intended to sell. But he also says the value added by direct labor could be inventory. But he also says it eliminates confusion over whether something is an investment or an expense. I don’t get it.

I interpret “direct” as labor done by their workers, as opposed to indirect labor which would be them buying some material from a different company which spent labor adding value to that material.

Jonah will explain local and global optimums later.